Tesla Mechanical Designs De-Risks Complex Sheet Metal Fabrication with Advanced Simulation Services

Firm utilizesn FEA to predict material behaviour, enabling the design of intricate, high-performance components and eliminating costly physical trial-and-error.

In modern product design, sheet metal is being pushed to its limits to create parts that are lighter, stronger, and more complex than ever before.”

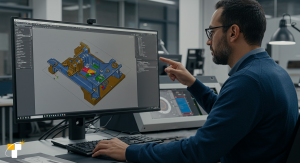

TX, UNITED STATES, September 26, 2025 /EINPresswire.com/ -- Tesla Mechanical Designs (TMD) is helping to solve a growing problem within the manufacturing industry by using advanced Finite Element Analysis (FEA) to ensure Sheet Metal Design is perfected before anything is built. As industries increasingly demand more lightweight and complex components for their products, the traditional approach of designing by experience and then building prototypes through a physical trial-and-error process can become costly and time-consuming. Structural Analysis by Tesla Mechanical Designs allows engineers to accurately predict issues such as tearing, wrinkling, and springback during the manufacturing process in a virtual environment. By focusing on this simulation-driven approach, Tesla Mechanical Designs is helping to ensure the successful fabrication of complex geometries such as those found in the automotive, aerospace, and electronics sectors.— Kuldeep Gajjar, Director, Tesla Mechanical Designs

𝐁𝐞𝐲𝐨𝐧𝐝 𝐅𝐥𝐚𝐭 𝐏𝐚𝐭𝐭𝐞𝐫𝐧𝐬: 𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐱𝐢𝐭𝐲 𝐨𝐟 𝐌𝐨𝐝𝐞𝐫𝐧 𝐒𝐡𝐞𝐞𝐭 𝐌𝐞𝐭𝐚𝐥

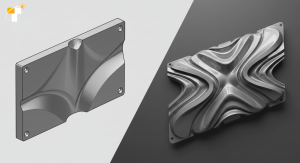

Goodbye Bent Boxes! The concept of simple bent boxes is a thing of the past. The need for sheet metal to perform multiple forming operations, to create complex and organic designs, is quickly on the rise. Industrial Product Designers need components to be stamped, deep drawn, hydroformed, and cut into shapes and sizes. These processes stretch and compress the material in ways that are difficult to predict with experience alone, especially when using modern high-strength alloys or aluminium. If the blank shape or the tools are misdesigned, the result can be a catastrophic failure in the shop, wasting material and tooling, and resulting in significant project delays.

Tesla Mechanical Designs mitigates these risks by integrating FEA Services directly into its Sheet Metal Modeling workflow, providing a clear path from digital concept to flawless physical part.

𝐒𝐢𝐦𝐮𝐥𝐚𝐭𝐢𝐨𝐧-𝐃𝐫𝐢𝐯𝐞𝐧 𝐃𝐞𝐬𝐢𝐠𝐧 𝐟𝐨𝐫 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐚𝐛𝐢𝐥𝐢𝐭𝐲

Tesla Mechanical Designs' simulation-first approach provides real-world benefits for clients looking to reach the limits of what is possible in Sheet Metal Fabrication—

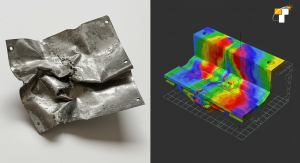

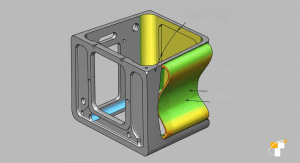

✔️ Formability Analysis - The process of forming metal into complex shapes can often cause the material to undergo unexpected stress concentrations. Engineers use simulation to accurately visualize the flow of material and concentration of stress during the forming process, and make changes to the part geometry, tool design, and material selection as necessary to ensure the piece can be manufactured successfully.

✔️ Springback Compensation - One of the most significant and most difficult issues to overcome when working with sheet metal is "springback". This is the natural tendency of the material to want to spring back partway towards its original shape after being formed. By accurately predicting springback using FEA, engineers can proactively compensate for it in the tooling design. This ensures the final component meets tight dimensional tolerances.

✔️ Thinning and Thickening - Simulation also allows to analyze areas of thinning, which are prone to failure, as well as thickening, which may cause wrinkles, in deep-drawn parts. This is important for both the structural integrity and cosmetic quality of the Custom Enclosure Design.

✔️ Reduced Prototyping - Validating the design virtually not only saves time in the design and engineering phase, but also results in a drastic reduction in the number of physical and expensive Metal Prototyping iteration. This reduces the overall cost and accelerates the entire Product Development timeline.

Simulation empowers Tesla Mechanical Designs’ clients to pursue truly innovative and complex designs and parts with confidence, backed by robust virtual validation.

𝐀𝐛𝐨𝐮𝐭 𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬

Tesla Mechanical Designs is an engineering and design consultancy providing data-driven solutions to complex manufacturing challenges. The firm is integrated with cutting-edge technology, which is complemented by deep, real-world engineering experience. The goal is to be a high-value partner for clients, enabling them to de-risk their product development cycle and innovate with confidence. By specializing in advanced simulation and analysis, Tesla Mechanical Designs helps manufacturers optimize their designs for performance, cost, and manufacturability from the very earliest stages of the design process.

Divya Dave

Tesla Mechanical Designs

+ +1 214-699-6163

email us here

Visit us on social media:

LinkedIn

Bluesky

Instagram

Facebook

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.